SPECIAL LINES

This section is dedicated to plastic cap denesters where they help automate and accelerate your manufacturing process. We take automation for granted so often thinking it may not be the right solution. However, Denesting a stack of cups to be placed into packaging or separating trays so that they can be prepped for use would take hours to do by hand, with these special lines you can minimise your time and resources so that you we can help you to maximise on your outputs and KPI's.

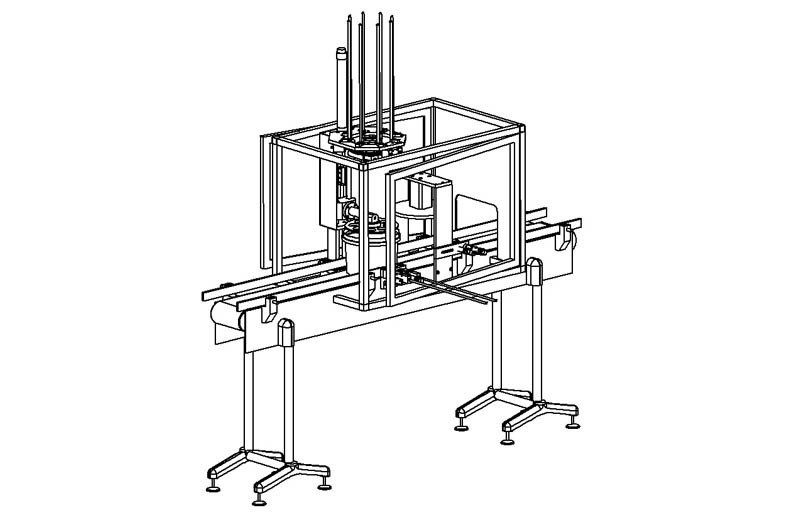

PLASTIC CAP DENESTERS

Our Suppliers produces automatic systems to destack piled plastic caps and press them both on pilable or non-pilable containers.

It is possible to produce automatic independent lines or to install the single units on existing packaging machines. New Paragraph

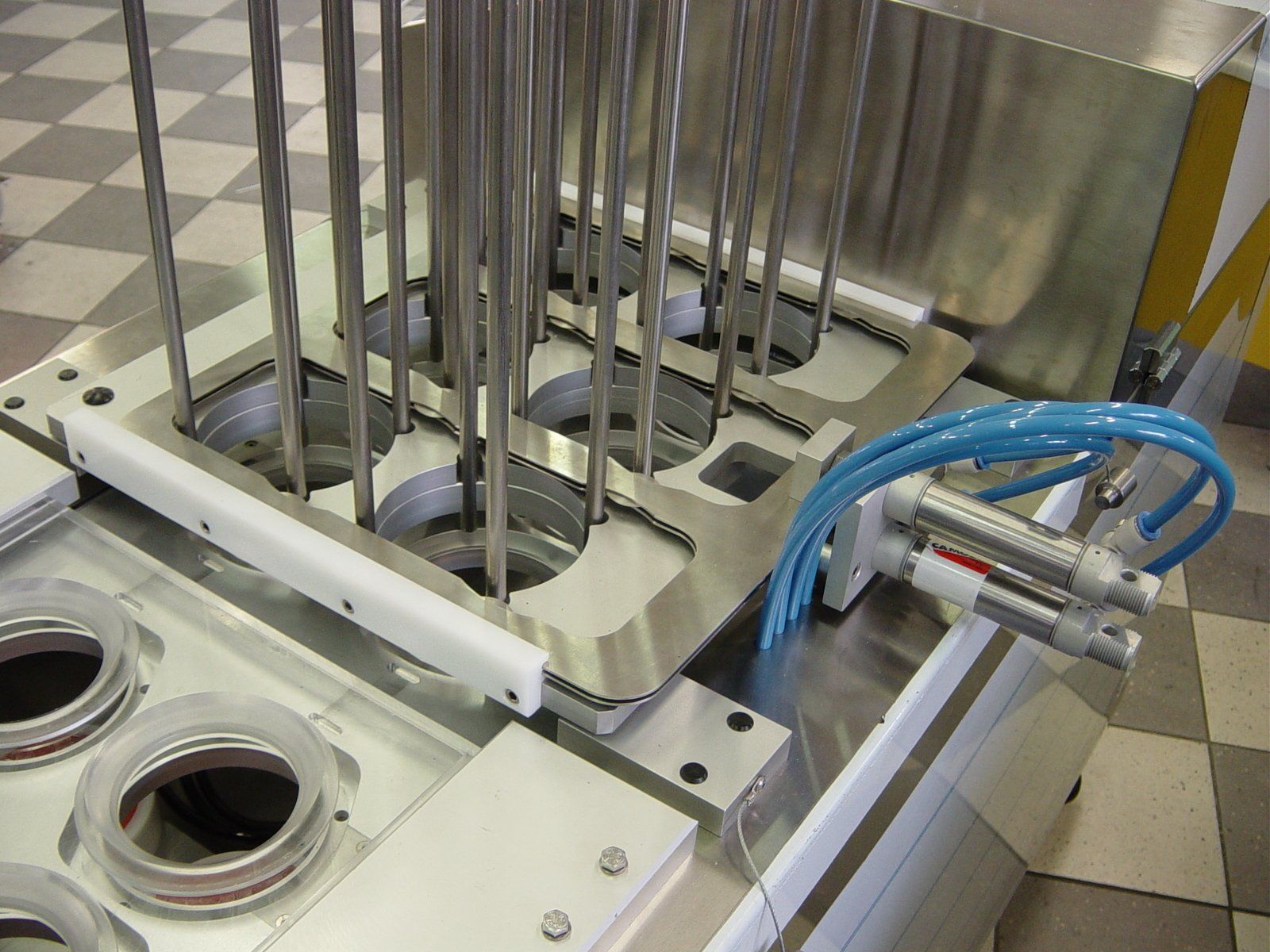

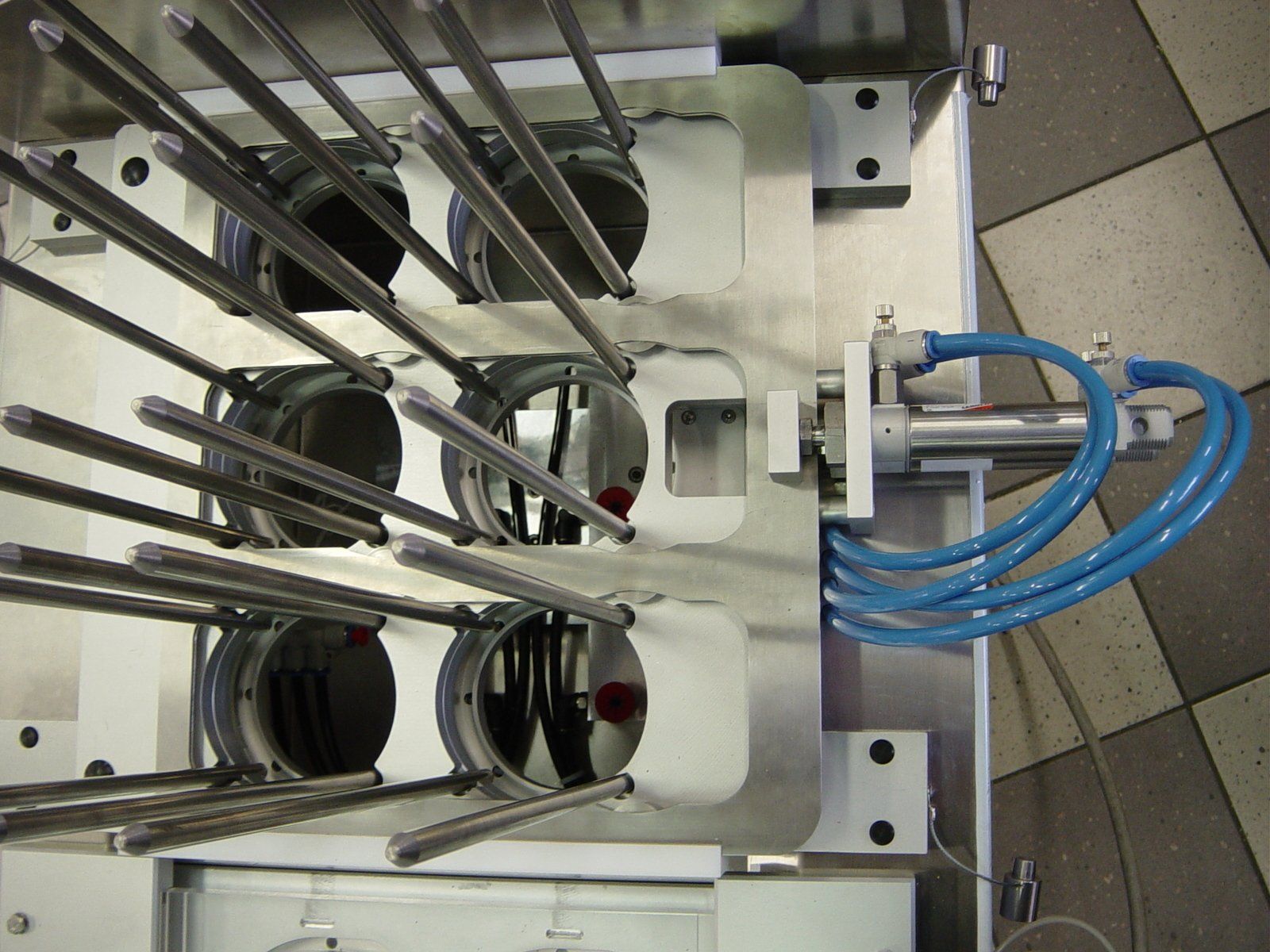

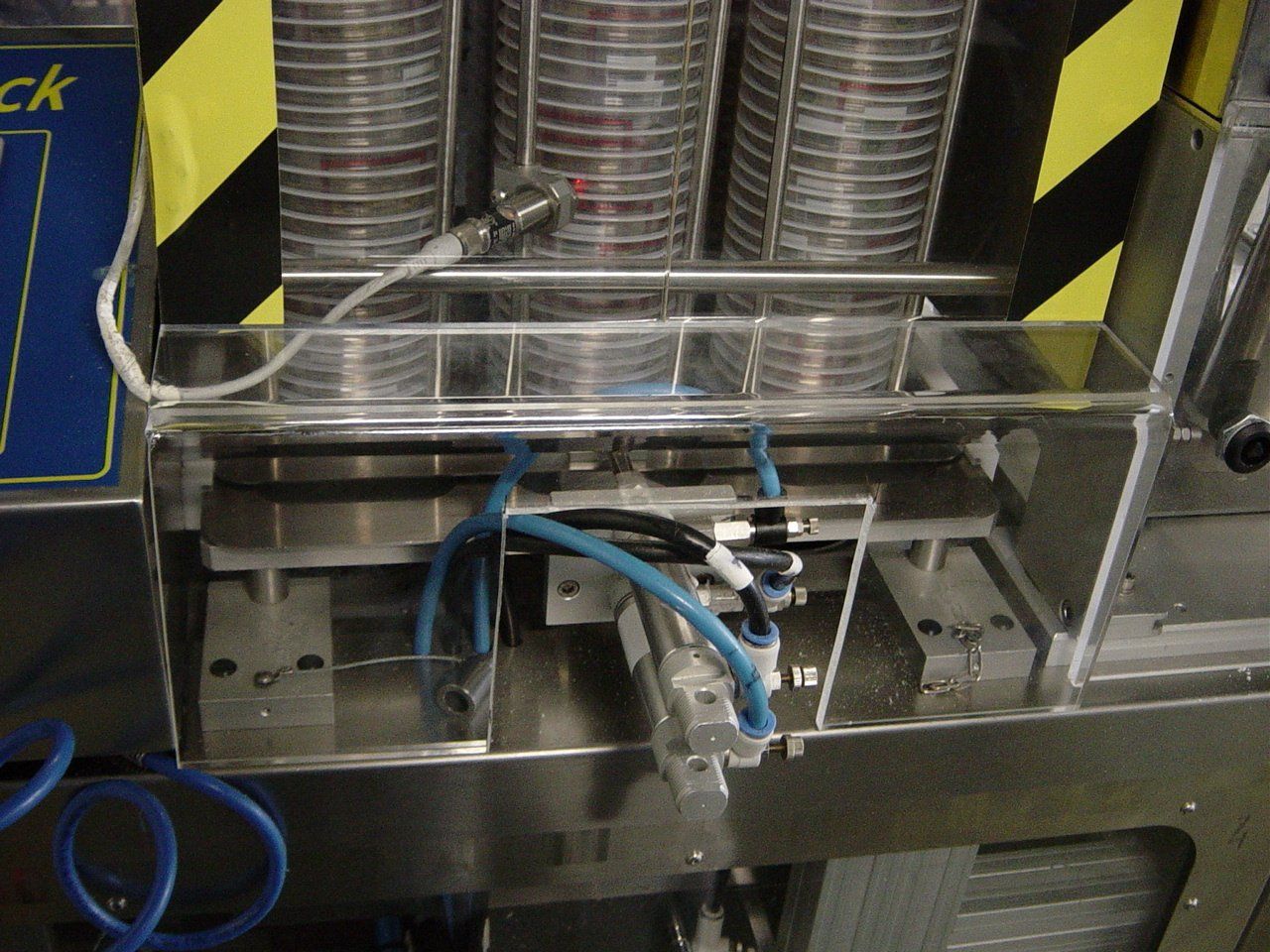

AUTOMATIC DENESTER FOR CLUSTER CAPS

- Containers infeed on conveyor belt

- Automatic system to sort the containers from single line to two lines

- Photocell to detect containers : “no container/no cap”

- Containers outdistancing system with pneumatic cylinders

- Automatic cluster cap placing to clamp 2 or 4 pots at once

- Alarm photocell “no cap/machine stops”

- Sensor cap catch

- Final collecting table

POWER 400/230 V. - 50/60 Hz

AIR SUPPLY required

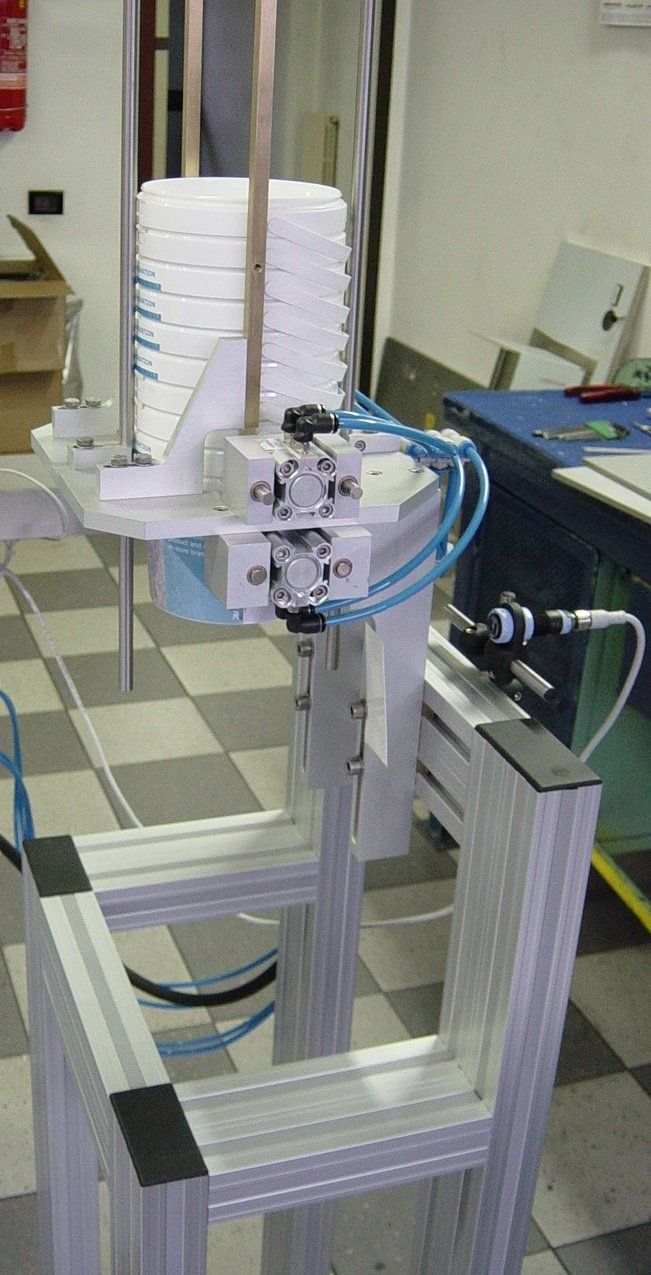

DENESTERS FOR BUCKETS WITH HANDLE

Automatic bucket denester. Can handle buckets with or without handle. Suitable to feed pails automatically on conveyor belts or packaging machines.

The unit can handle more sizes thanks to simple adapting kits.

AIR SUPPLY - Yes

OUTPUT - 500/1000 pcs/H

SEMI AUTOMATIC DOSING UNITS

- Volumetric dosing unit – volume adjustable up to 500 cc

- Cycle start by pedal or by button

- Can be assembled on table -top or floor standing support

- Feeding Hopper

AIR SUPPLY 12 NL/cycle

AIR PRESSURE 6 bar

OUTPUT 10 cycles/min

FILLING VOLUME 500 cc.

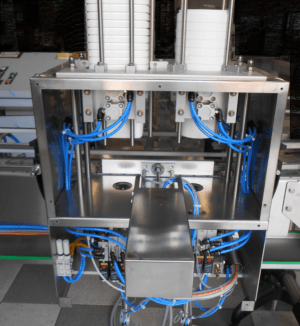

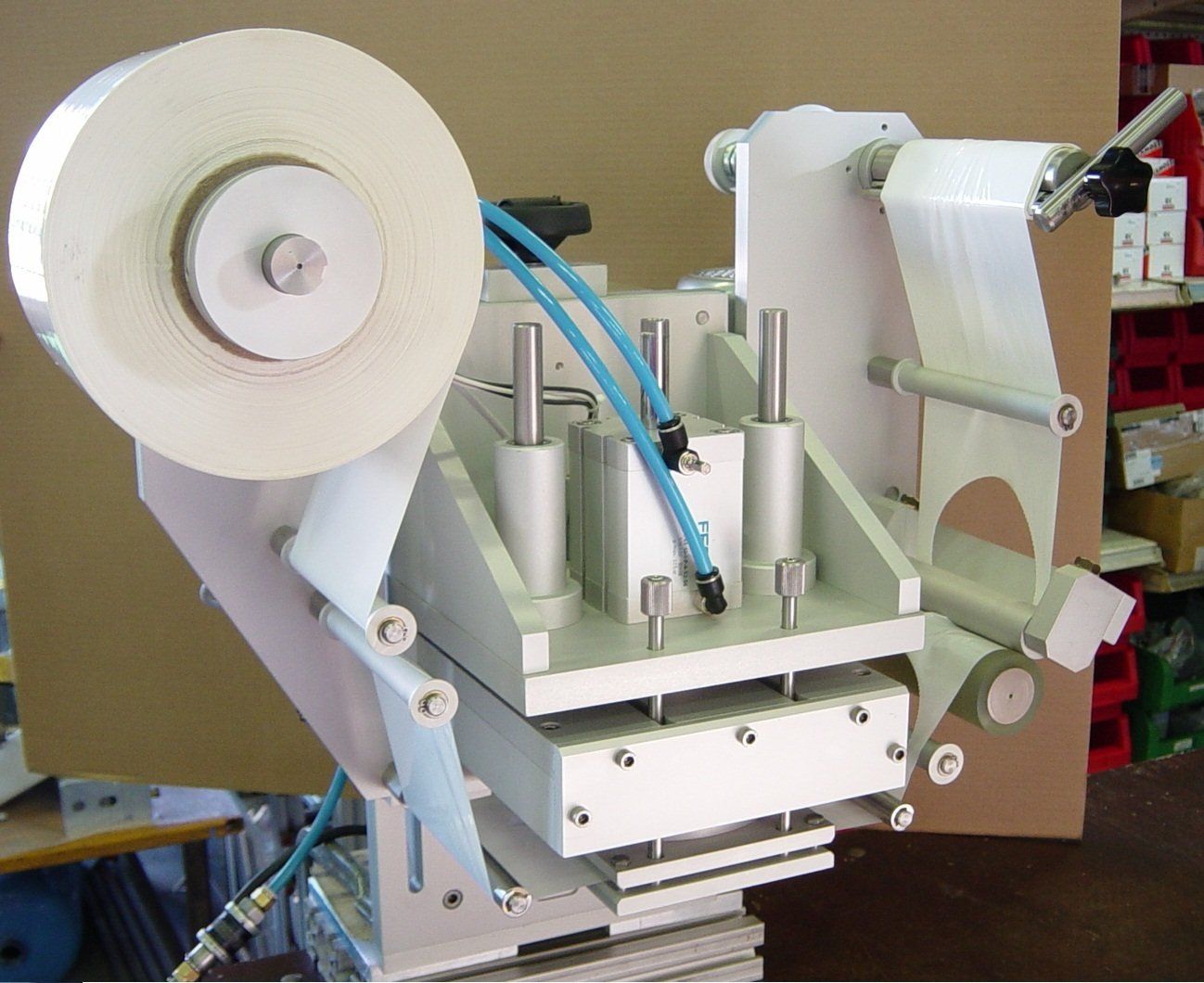

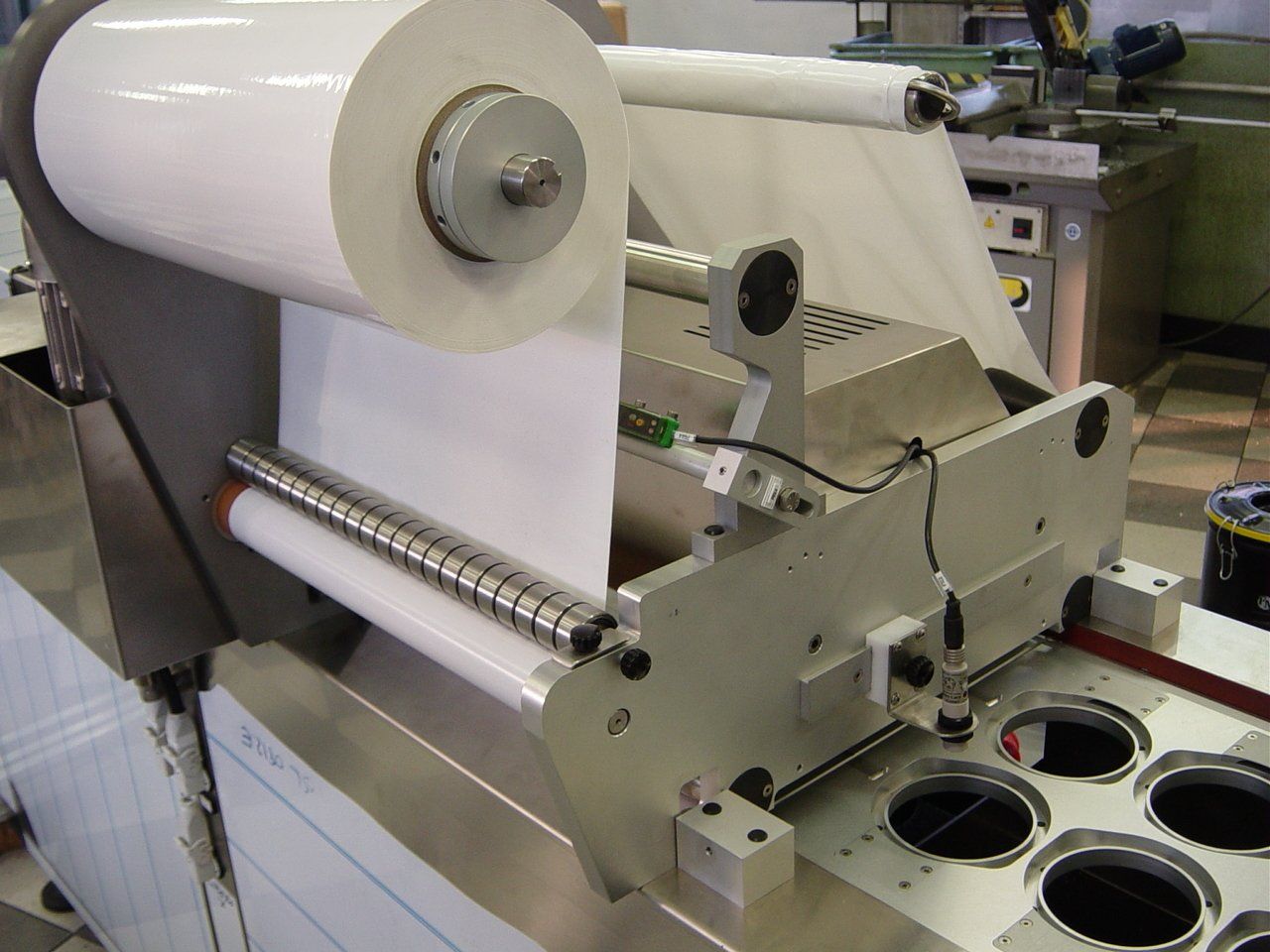

SEALING HEADS

The heat-sealing heads are able to seal and cut film in roll on containers, both stackable or not. They can be assembled on our packaging lines or on other manufacturers’ machines (even on existing lines) .can realize tested for sealing more containers at a time.

The heads provide an automatic unwinding system for film – that based on the requirements, can be lateral or frontal – welding on the edge of the container, cutting the film with the possibility of obtaining a tab for easy opening and scrap rewinding.

It is possible to prepare heads sealing one or more containers at once.

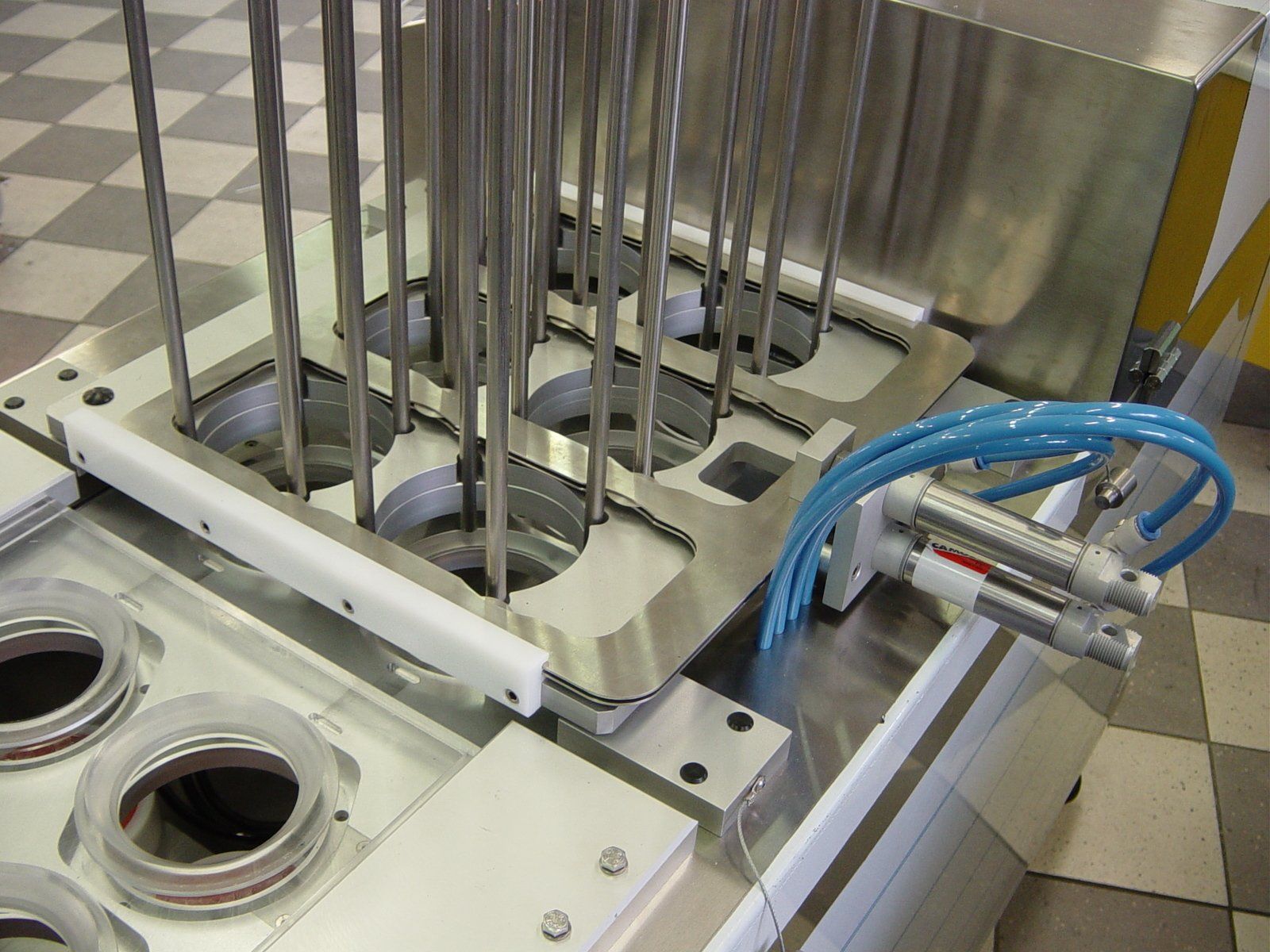

AUTOMATIC FEEDER FOR TRAY DISPENSER

Automatic feeder of empty trays for the cup denester on the model SLALOM.

In this case the machine packs 6 containers at once with a productivity of 6 cycles/minute.

The dispenser autonomy is of about ten minutes.

Thanks to this feeder, the dispenser is continuously charged with empty trays, avoiding machine stops. The feeder has a capacity enough to grant one hour autonomy to the machine.

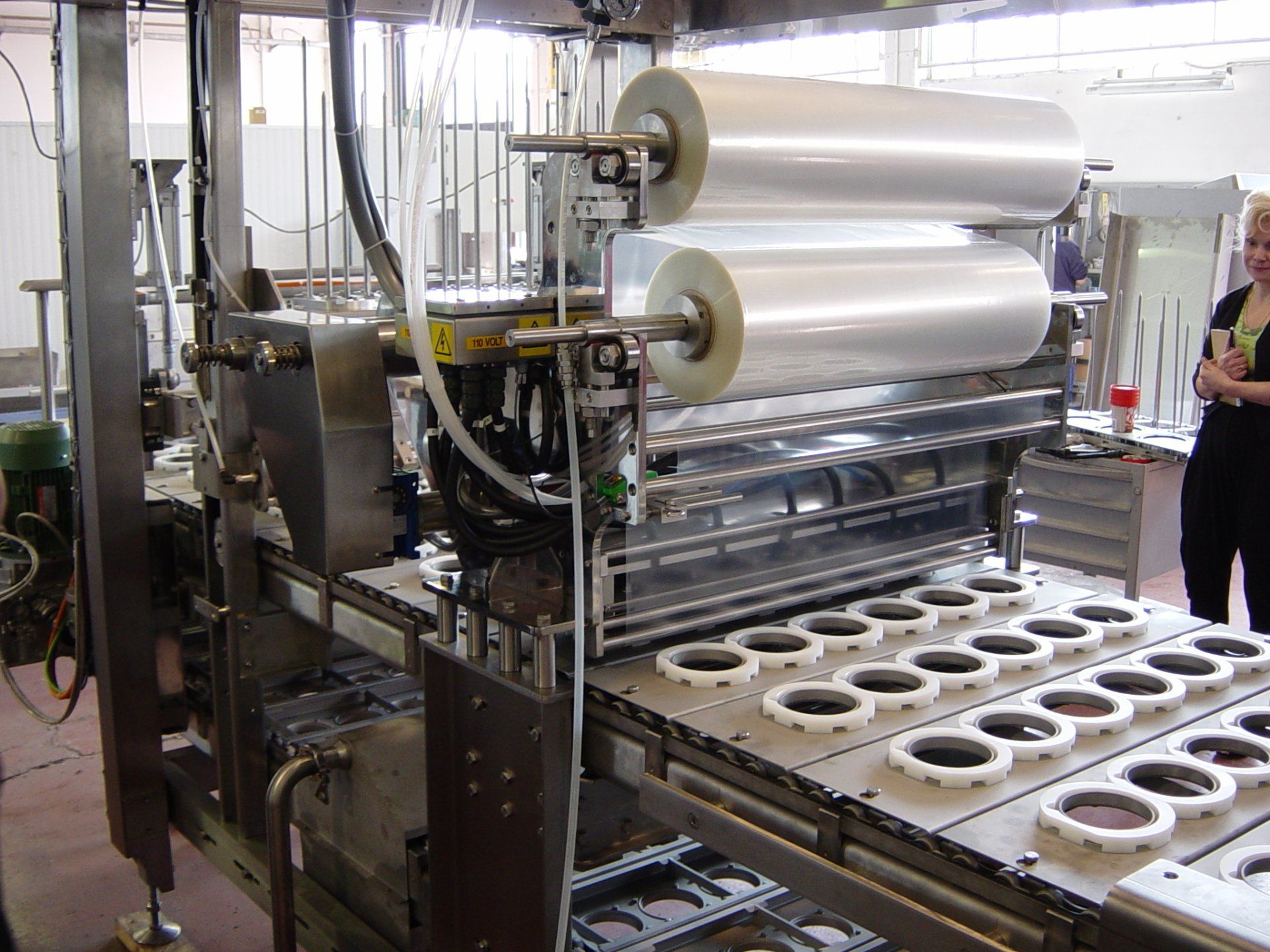

AUTOMATIC TRAY SEALER FOR ROUND POTS

Products: Parmesan cheese grated / sticks / flakes

Machine functions:

- Pot denester

- Cheese dosage

- Pots vibration to adjust the product inside the tray

- Cheese pressure

- Cap denester

- Film sealing and packing in ATM with gas analizer in the vacuum box

- Ejection

POWER 380V, 50/60Hz 3P+N+T

POWER

CONSUMPTION 7 KW

AIR SUPPLY 50 NL/ciclo

WEIGHT - kg. 750

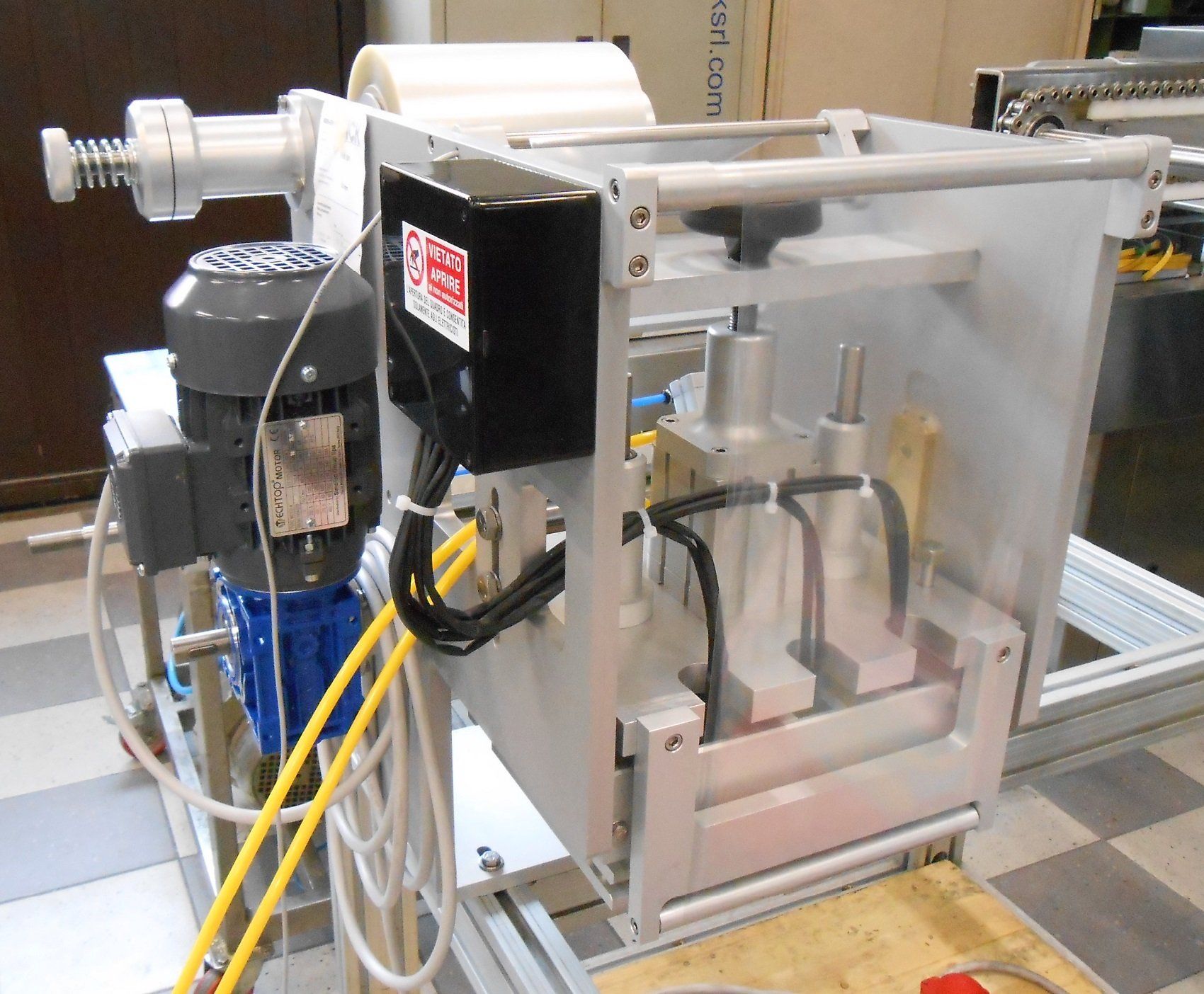

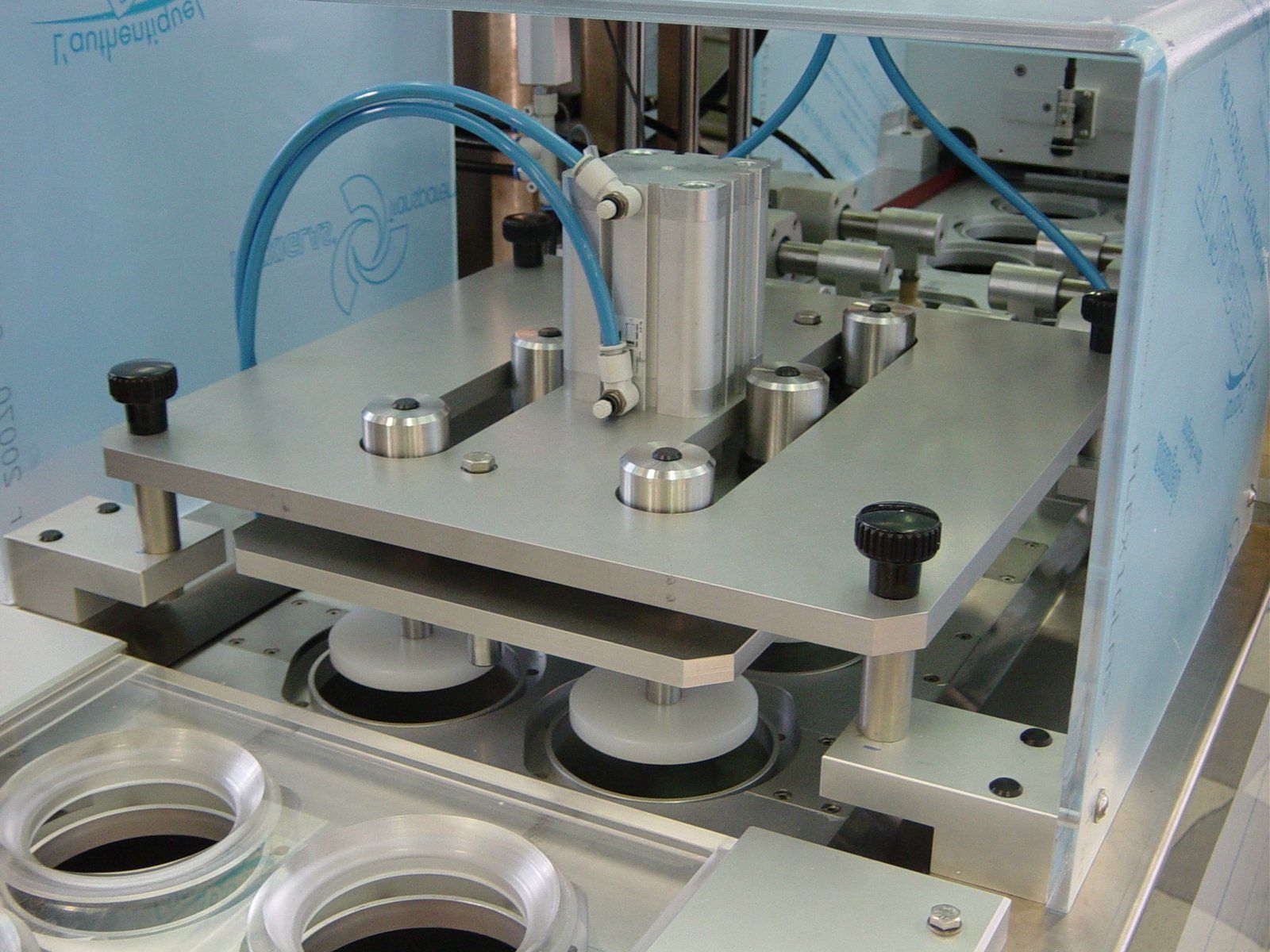

MILK FILLER - FILLING AND CLOSING SYSTEM

TECHNICAL FEATURES

Control : PLC

Pneumatic Components : CAMOZZI

Productivity : 600PCS/H

Tension : 400V - 50/60 Hz - 3f

Electric Consumption : 1KW

Air Consumption :15 NL/cycle - 6 bars

Dimension : 110 x 70 x 200 (h) cm