LABELLING

ENTRY LEVEL TABLE TOP LABELLERS

LOW BUDGET RELIABLE LABELLERS

This is the innovative "low-cost" labeller which revolutionizes the constructive concepts of a labeller joining constructive simplicity, good design, ease of use to a really interesting price.

Standard features:

- Maximum width of labels: 140 mm

- Maximum length of labels: 350 mm

- Maximum speed: up to 20 mt/min

- Maximum roll diameter: 250 mm

- Core diameter: 45/76 mm

- Main frame: Steel with niploy treatments

- External cover: Shockproof ABS

- Dispensing blade: Adjustable 0-90°

- Electronic control: Integrated control board

- Speed adjustment: By potentiometer

- Stop delay adjustment: By potentiometer

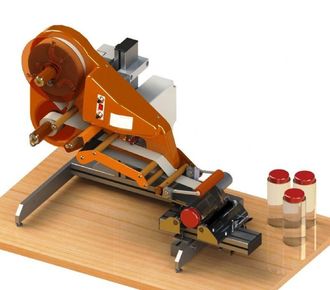

Semiautomatic labeller is the ideal solution for application onto cylindrical products: bottles, flacons, cans, jars.

Standard features:

- Maximum width of labels: 140 mm

- Maximum length of labels: 350 mm

- Maximum speed: up to 20 mt/min

- Maximum roll diameter: 250 m

- Core diameter: 45/76 mm

- Main frame: Steel with niploy treatments

- External cover: Shockproof ABS

- Dispensing blade: Adjustable 0-90°

- Electronic control: Integrated control board

- Speed adjustment: By potentiometer

- Stop delay adjustment: By potentiometer

- Positioning device with motorized rolls

- Top table base support

- Applicator roll with start sensor

LABELLERS FOR HOUSEHOLD AND DRY ITEMS

LABELLING FOR FRONT AND BACK

Labeling systems for the application in simultaneous of dual front/back pre-printed labels on reel. Solution suitable for flat, round, conical and oval products. The machine is equipped with conveyor belt, in various versions and sizes. The controls are managed from a single touch screen unit with the ability to record 99 recipes.

Choices paper passage, speed and installation of a dry or hot overprinting group or printer for commercial data entry (ingredients, logos, dates, codes).

The loading and unloading of the products on the conveyor belt can be done manually, through infeed rotary table or directly from the existing production line.

LABELLING HEADS

Automatic labeling solutions for label applications on flat products. With the adoption of a side counter roller it is also possible to apply labels on round products.

The solution is done by a label head to be installed on an existing conveyor belt,through a column or a half column in chromed stainless steel, adjustable in height and depth, with an asymmetrical base with locking system and adjustable feet or self-locking wheels.

The touch screen control unit offers the possibility to handle external signals and to store relative parameters up to 10 different formats of labels.

OVERPRINTS

Automatic overprinting system to print alphanumerical data, with hot (thermal transfer) or dry (embossing) on flat carton boxes and similar. Machine complete of vacuum conveyor to hold products and loading hopper. Suitable for flat boxes and bags. Possibility of automatic unloading of products.

The machines are equipped with touch screen control unit and, as option, are available with:

- System with camera to check the application of label.

- System with camera to check the correct label position.

- System with camera to check correct barcode printing on the label.

APPLICATION FOR PRINT & APPLY

Labelling machine, automatic dual-function, models Print & Apply Touch Screen adapted for top, side and bottom application on flat, round and conical products.

Possible job option (print and applies or labelling only), application speed, print width, manufacturer and printer connection mode (PC, USB, NETWORK) depending on production needs. Base management software included.

On demand, complete system mounted on support column to be installed on existing line.

The label application can be done on moving products by peeling blade (mod. P/A extra LM version), or on no-moving products by vacuum pad (mod. P/A extra PN version).

APPLICATION FOR TOP & BOTTOM

Labeling systems for top, side, bottom application of pre-printed labels on reel. Solution suitable for flat, round, conical and oval products. The machine is equipped with conveyor belt, in various versions and sizes. The controls are directed from a single touch screen unit with the ability to record 99 recipes.

Choices paper passage, speed and installation of a dry or hot overprinting group or printer for commercial data entry (ingredients, logos, dates, codes).

The loading and unloading of the products on the conveyor belt can be done manually, through infeed rotary table or directly from the existing production line.

APPLICATION FOR WRAP AROUND

AUTOMATIC SOLUTIONS

Labeling systems for wraparound application of pre-printed labels on reel. Solutions suitable for round and conical products. The machine is equipped with conveyor belt, in different versions and sizes. The control of the parameters is managed by a touch screen control box unit with the ability to record 99 recipes.

Choices paper passage, speed and installation of a dry or hot overprinting group or printer for commercial data entry (ingredients, logos, dates, codes).

The accuracy of the application is guaranteed by a counter roller device.

The loading and unloading of the products on the conveyor belt can be done manually, through infeed rotary table or directly from the existing production line.

By removing the side counter roller device, it’s also possible the application of labels on flat products.

TABLE TOP APPLICATION

Semi automatic system able to apply pre-printed lables on round and flat products.

Possibility to install microswitch or photocell for labels reading. An overprinting unit (dry or hot) can be installed for alphanumerical data printing.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

APPLICATION WRAP AROUND WITH SECURITY SEAL

Labeling systems for wraparound application of pre-printed labels on reel. Solutions suitable for round and conical products. The machine is equipped with conveyor belt, in different versions and sizes. The control of the parameters is managed by a touch screen control box unit with the ability to record 99 recipes.

Choices paper passage, speed and installation of a dry or hot overprinting group or printer for commercial data entry (ingredients, logos, dates, codes).

The accuracy of the application is guaranteed by a counter roller device.

The loading and unloading of the products on the conveyor belt can be done manually, through infeed rotary table or directly from the existing production line.

By removing the side counter roller device, it’s also possible the application of labels on flat products.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Use our Showroom for a FREE trial

Address: Showroom and Product Test Centre

48 College Road

Perry Barr

Birmingham

B44 8BP

Mail: sales@haylespackaging.co.uk

Phone: +44 121 331 1914