SPECIALISED CARD AND LEAFLET FEEDER SYSTEMS

AUTOMATIC FEEDERS

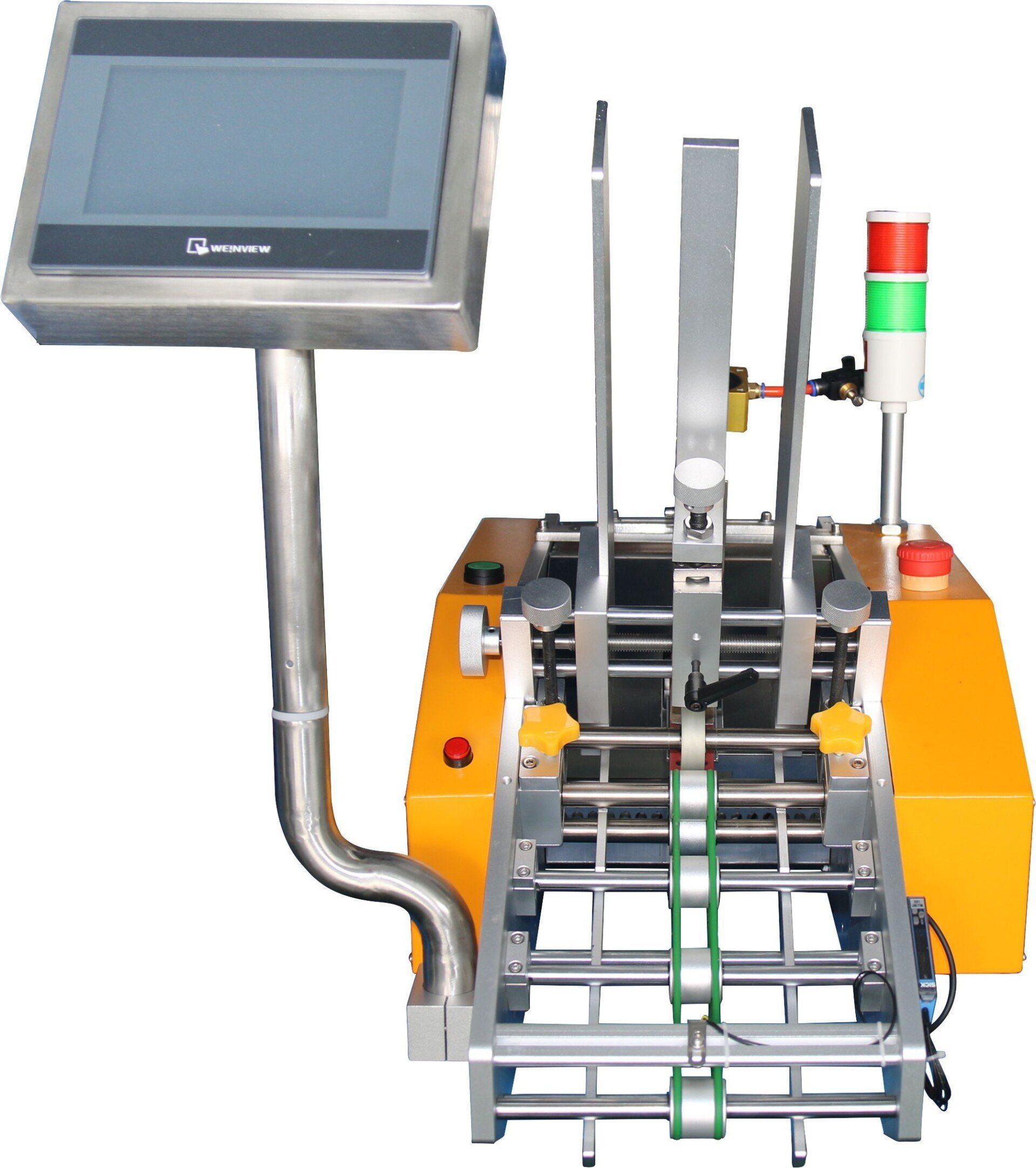

Feeder for feeding and

gluing machines, for precise positioning of products onto carrier materials

Standard features:

- Feeding width 300 mm standard

- Feeding at the exact position and/or gluing of the products

- 3-S-System: Exact air gap adjustment of all parameters via digital setting display unit (patent pending)

- Product run-time monitoring for missing sheet detection

- Min. stack monitoring in the magazine

- Infinitely adjustable feeding speed

- Highly dynamic drive via AC servo motor

- Intermediate belt for products smaller than 60 mm

- Exit extension 300 mm with flat belt, width 20 mm and knife edge for exact feeding

- Spring mounted pressure bar with rolls, tilt table with upper part of the exit extension

- Encoder included

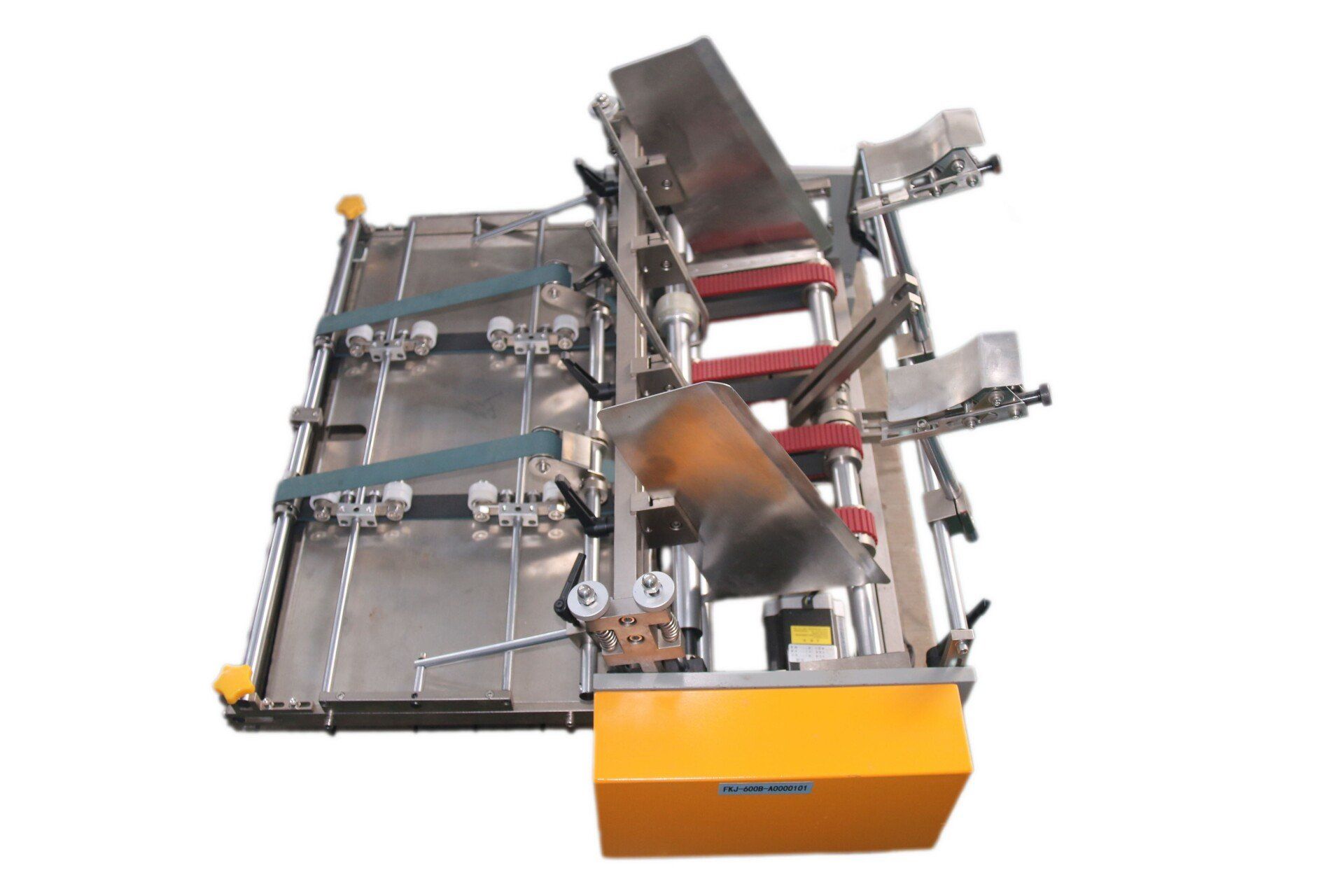

The universal feeder for flat products (paper, cardboard, plastic, film, etc.)

Can be integrated in paper converting, subsequent processing and wrapping machines

Standard features:

- Feeding width 250 or 300 mm standard

- Product magazine 600 mm easily accessible for loading, with integrated signal lamp

- Swivelling exit extension 150 mm with flat belts

- Drive actuated via powerful DC motor

- Max. 150 m/min. / up to 1400 products/min.

- (continuous) / up to 600 prod. / min. (cycled)

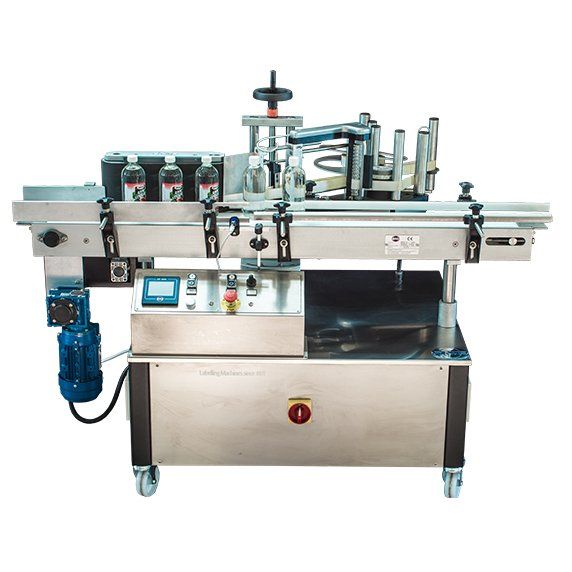

The feeder for flat products (paper, cardboard, plastic, film, etc.) in the middle performance range

Standard features:

- Feeding width 300 mm standard

- Product feeding single

- Product magazine 300 mm

- Swivelling exit extension 150 mm with flat belts

- Drive actuated via powerful DC motor

- Max. 80 m/min. / up to 80 products/min. (DIN A4, cycled)

The perfect entry model friction feeder for the separation of flat products. This feeder offers outstanding performance and quality at an affordable price.

Standard features:

- Feeding width 235 mm standard

- Single product feeding

- Central air gap adjustment from 0.1 up to 5 mm

- Min. stack monitoring in the magazine

- Feeding speed up to 40 m/min

- Drive actuated via DC motor

Use our Showroom for a FREE trial

Address: Showroom and Product Test Centre

48 College Road

Perry Barr

Birmingham

B44 8BP

Mail: sales@haylespackaging.co.uk

Phone: +44 121 331 1914