PRINT AND APPLY LABELLING SYSTEMS

VERSATILE PRINT AND APPLY LABELLING SYSTEMS

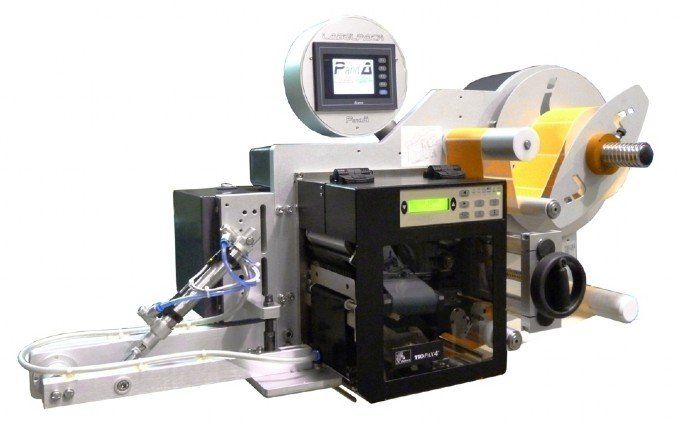

Print & apply unit for one side application.

and thermal transfer print engines.

Standard features:

- Reel holder with mechanical un-winder

- Anodized aluminium reel discs with screwed locking system

- Motorized liner re-winder with locking device

- Applicator module with swinging vacuum pad pneumatically activated and spreading roll.

- Integrated control unit with PLC

- Cycles labelling control

- Alarms and external signal interfaces

- Operator panel with colour touch-screen and swivelling support

Print & apply unit for front side application.

Standard features:

- Reel holder with mechanical un-winder

- Anodized aluminium reel discs with screwed locking system

- Motorized liner re-winder with locking device

- Applicator module AF-300

- Integrated control unit with PLC

- Cycles labelling control

- Alarms and external signal interfaces

- Operator panel with colour touch-screen and swivelling support

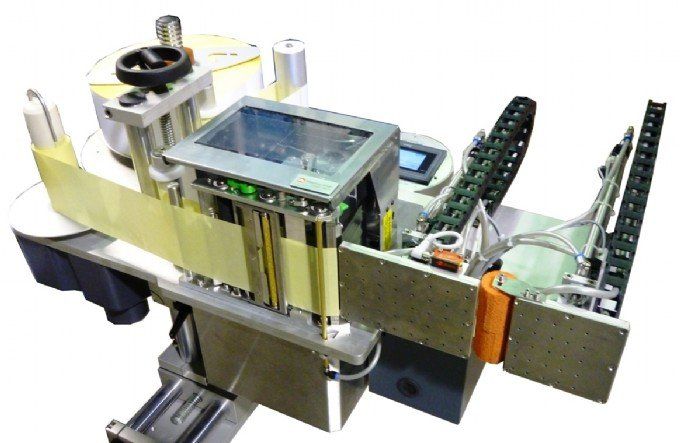

Print & apply unit for corner application onto two adjacent side of a boxes.

Standard features:

- Reel holder with mechanical un-winder

- Anodized aluminium reel discs with screwed locking system

- Motorized liner re-winder with locking device

- Applicator module AL2 with double pneumatic cylinder.

- Integrated control unit with PLC

- Cycles labelling control

- Alarms and external signal interfaces

- Operator panel with colour touch-screen and swivelling support

PRINT AND APPLY PALLET LABELLING SYSTEMS

Print & apply solution completed with total protection for the integration under particular environmental conditions like dusty environments or with non optimal temperatures for the management of the thermal transfer print engine.

Standard features:

- Reel holder with mechanical un-winder

- Anodized aluminium reel discs with screwed locking system

- Motorized liner re-winder with locking device

- Applicator module AL-300

- Integrated control unit with PLC

- Cycles labelling control

- Alarms and external signal interfaces

- Operator panel with colour touch-screen and swivelling support

- Total protection for rough environment

This Print and Apply has 200 dpi resolution, it is the ideal solution for the integration onto end of packaging line at low performances.

Standard features

- Reel holder with mechanical un-winder

- Anodized aluminium reel discs

- Motorized liner re-winder

- Print engine unit: SATO LT 408

- Applicator module AL-300 AF-300

- Separated box electorni control (ER)

- Cycles labelling setting

- Alarms and external signal interfaces

- Operator panel with numeri display and functions keypad.

This print & apply printer can print A5 label onto one or two or three sides of a pallet in any particular environmental conditions. It is a sturdy mechanical frame with a complete protection, available in stainless steel on request, is the main feature of this solution, which allow to integrate this print & apply solution onto pallet-packaging line in any harsh environmental condition. The applicator unit can be configured to apply one label onto the front side and the second label onto the adjacent side with pallet standing in one position or in two position, and upon request could have also the possibility to apply the third label on the back side of the pallet.

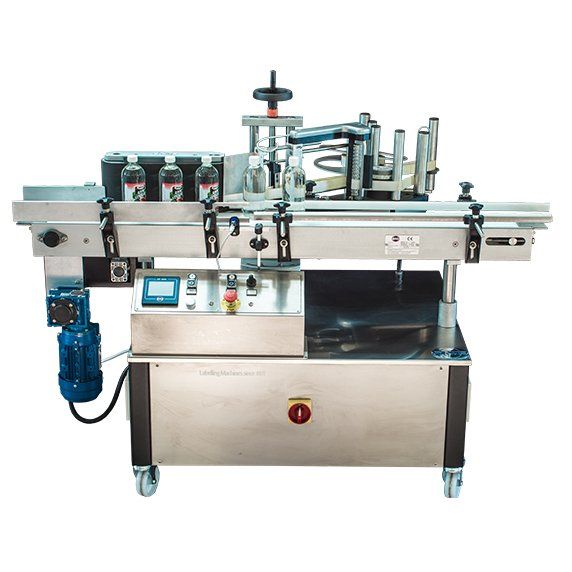

Print & apply unit for integrates onto packaging line or machines with small space.

Standard features:

- Reel holder with mechanical un-winder

- Anodized aluminium reel discs with screwed locking system

- Motorized liner re-winder with locking device

- Customized applicator module AL

- Separated control box unit with PLC

- Cycles labeling control

- Alarms and external signal interfaces

- Operator panel with color touch-screen

Use our Showroom for a FREE trial

Address: Showroom and Product Test Centre

48 College Road

Perry Barr

Birmingham

B44 8BP

Mail: sales@haylespackaging.co.uk

Phone: +44 121 331 1914